BYERS AND VFA SOLUTIONS

A Strategic Partnership with a Singular Goal of Delivering Clean, Emissions-Free Air

State-of-the-Art sustainable solutions that combine industrial-scale odor control with air filtration and purification technology for the removal of airborne viruses – including COVID-19 – pathogens and dust particles.

Thanks to the strategic partnership with Dutch-based VFA Solutions, Byers Scientific has brought patented next-generation clean air technology to North America.

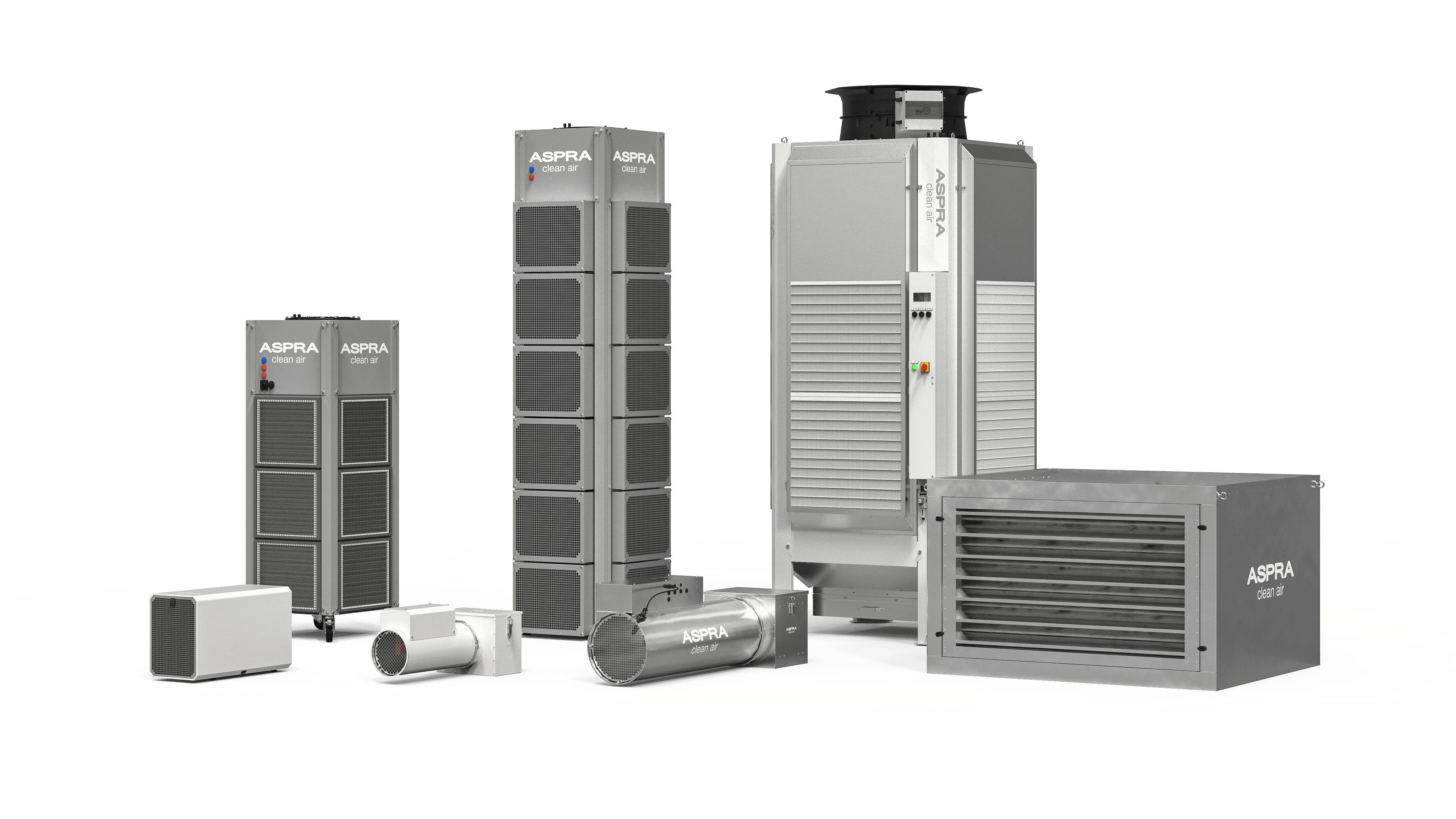

VFA’s patented ASPRA® Electrostatic Precipitation and Filtration (ESP&F) technology is now integrated into various Byers’ products, including the MT-Series of molecular filtration systems.

With scalability from 2,000 to 6,000 CFM, the MT-Series of molecular filtration systems with ASPRA® technology purifies the air, thereby improving Indoor Air Quality (IAQ) and supporting workplace safety compliance, while proactively controlling odors before they become a nuisance.

A significant advantage of incorporating ASPRA® into existing HVAC and other air handling systems is that there is virtually no infrastructure re-design necessary due to ESP&F’s inherent adaptability and minimal static pressure drop, making it perfect for use in:

- Airports and Transportation Facilities

- Commercial Agriculture

- Corporate Offices

- Educational Facilities

- Entertainment Venues

- Food Preparation Facilities

- Health and Fitness Facilities

- Hospital and Healthcare Facilities

- Industrial Manufacturing Facilities

- Retail Complexes

- Warehouses

HEPA |

Ultraviolet(UVC/UVGI) |

||

|---|---|---|---|

| Description |

All aerosols (particles and pathogens) in the airflow are electrically charged and captured on a static medium in the system |

(Fiberglass) Filters for the capture of fine particles in the airflow |

Pathogens are exposed to UV-light (electromagnetic radiation) for deactivation |

| Removes aerosols |

X |

||

| Captures viruses and bacteria |

X |

||

| Captures Particulate Matter |

X |

||

| Particle size range | All | Limited | Can’t remove Particulate Matter |

| Deactivates viruses |

X |

|

|

| Effect on gases/VOC |

X |

X |

|

| Ozone safe | UV-type dependent | ||

| Energy consumption | Low | High | High |

| Pressure drop | Low | High | Low |

| Conditions for optimal operation | No additional measures | Pre-filtration with other filters | Correct UV-doses (adequate exposure time and intensity) |

Let’s clear the air on some misused definitions.

Why ASPRA® Is Better:

Exceeding HEPA Standards – Without Using a “HEPA-Style” Filter

VFA Solutions’ patented ASPRA® air purification technology is a highly efficient system that achieves up to E12-H13/HEPA classification (according to NEN-EN 1822 and DIN EN ISO 29463-5:2019 standards) without using a traditional HEPA-style filter.

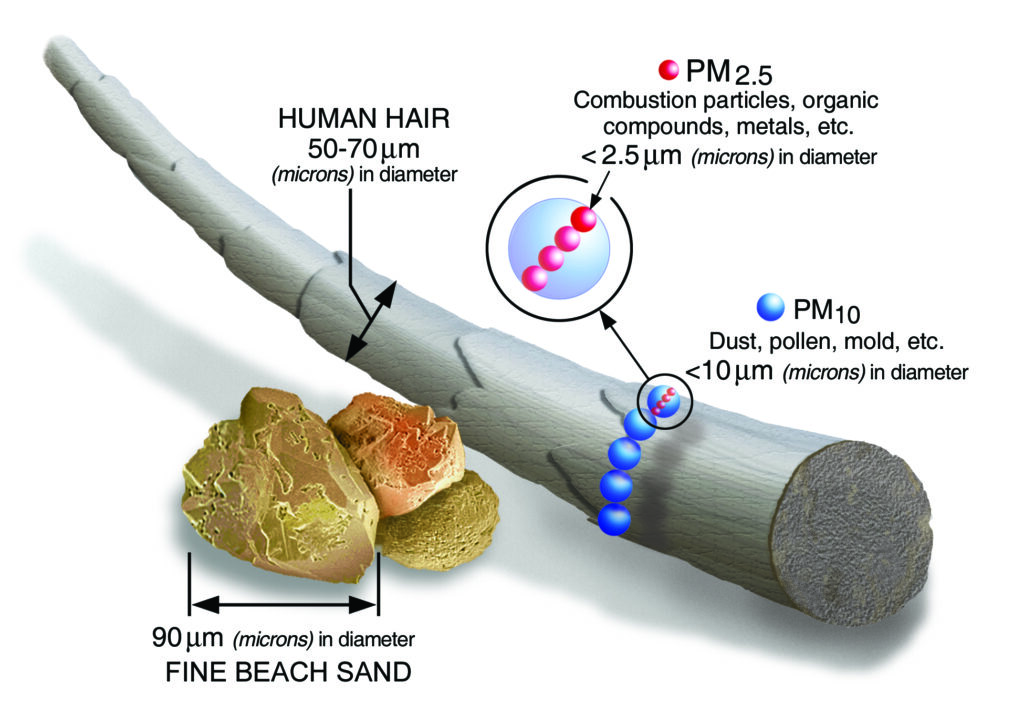

- Purifies for particulate matter size 0.03-0.30µm

- Equivalent to 30 Nanometers

- Botrytis and Powdery Mildew: 10µm

- Reduced Air Flow: 175m3/h to 300 m3/h

- Greater than 99.8% Removal Efficiency

ASPRA® is more cost-effective, creates less waste, and delivers substantial energy savings when compared to conventional air filters.

Image from www.epa.gov

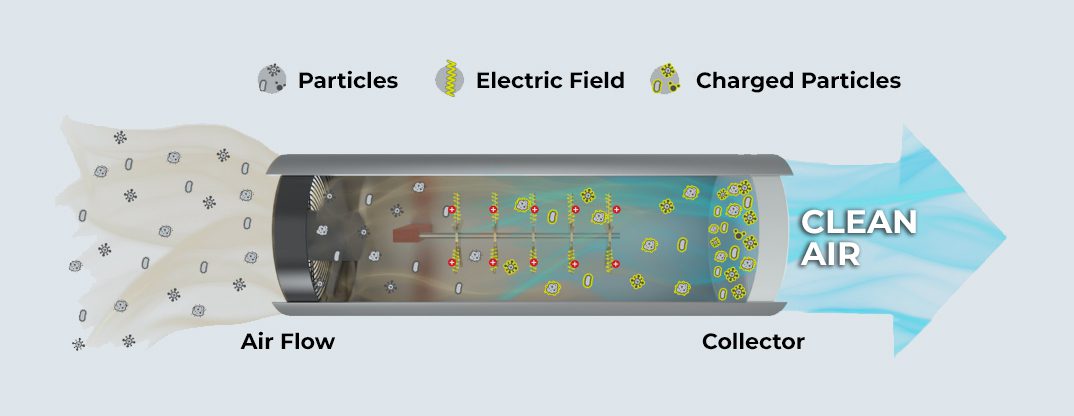

How ASPRA® Works:

-

Unhealthy air is pulled into the device

-

The particles (smoke, viruses, bacteria, fungi, particulate matter, pollen, etc.) in the air are electrically charged as they pass through an electrostatic field

-

Biological particles, such as viruses, are deactivated directly in the device

-

The particles, pathogen residues and aerosols are captured on a proprietary collector (particle filter) inside the device

-

Clean, purified air leaves the device

“Electrostatic filtration is the future.”

As the North American strategic partner of Dutch-based VFA Solutions, we are proud to share in their mission of providing clean air everywhere. Whether in an office, airport, school or agricultural facility, leveraging ASPRA®’s innovative air purification technology with the power of real-time data, provides transparent reduction of particulate matter, as well as airborne pathogens for better indoor air quality (IAQ).

PURIFYING THE AIR

ASPRA® removes a wide range of airborne contaminants without needing to use conventional textile filters or other expensive filters:

- Dust

- Particulate matter (PM10, PM2.5, PM1)

- Ultrafine particulate matter (PM0.1, submicron and nano-particles)

- Microbiological contaminations (viruses, bacteria, fungi, spores and pollen)

- VOCs (volatile organic compounds)

Fine Dust

Viruses

Particulate Matter

Fungi/Mold

Bacteria

VOCs

Key Benefits

Healthy Environment

Greater than 99.8% removal efficiency of:

- Indoor airborne Particulate Matter (PM)

- Fine particles and Ultra-Fine Particles (UFP’s)

- Allergens, pathogens, microbes

Effective Filtration

- Certified tests EU-class 10-11

- Expandable efficiency to EU 12-13, comparable to HEPA

- Kills/deactivates bacteria and viruses

Low Maintenance Costs

- No UV bulbs to break and/or replace

- Superior energy efficiency

- No need for expensive HEPA filter replacement

Flexible Deployment

- Seamless integration into existing HVAC

- Stand-alone Non-HVAC models available

- Low-impact space requirement

Get Free Industry Insights

Stay up-to-date on the latest advancements in odor and emissions technology.

Subscribe to our newsletter for industry updates, company news, and more.

"*" indicates required fields

Ready to effectively tackle odor and improve Indoor Air Quality?

Listen to this exclusive podcast interview with Marc Byers, Founder and President of Byers Scientific, and Eliane Khoury, Founder and CEO of VFA Solutions, who discuss how their combined solutions tackle problematic odors – while also purifying the air with the most sustainable technology on the market today.